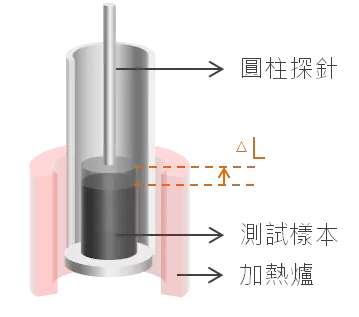

TMA, Thermal Mechanical Analyzer

TMA uses a heating furnace to provide a stable environment for heating and cooling, recording minute dimensional changes in the sample during the process using a probe and sensors. The following are the measurements that can be conducted with TMA:

CTE, Coefficient of Thermal Expansion Measurement

This measurement involves assessing the change in dimensions of a material as a function of temperature. TMA specifically measures the dimensional change in the Z-axis direction, which provides the linear coefficient of thermal expansion of the sample.

Tg, Glass Transition Temperature Measurement

The glass transition temperature is the temperature at which a polymer material transitions between a glassy state and an elastic state. There is a noticeable change in the CTE of the material before and after this transition due to the structural differences. TMA detects this change in CTE to determine the glass transition temperature of the sample.

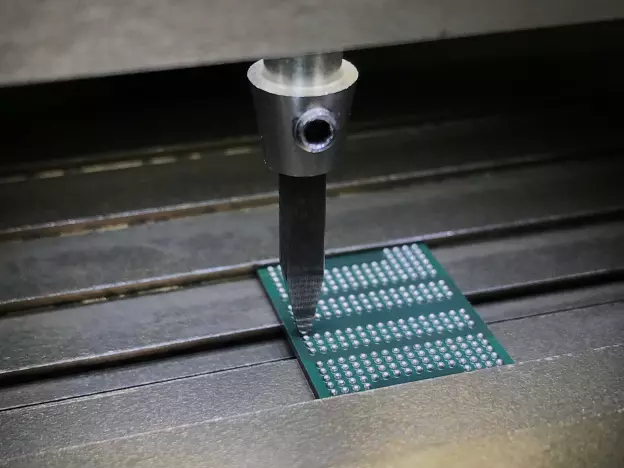

Shear Test & Pull Test

This method is used to evaluate the bond strength of solder materials and SMD components after soldering. In the shear mode, it tests the shear force of solder ball bumps or SMD components, with precise control over the height and shearing speed. Additionally, using a tweezer-type chuck, tensile strength tests can be performed on solder ball bumps.

Tensile Test

This method is employed to test the bond strength of IC components in various PCBA products, and can be combined with other analytical requirements for component removal. Additionally, the tensile testing machine is used to perform material tensile tests to evaluate the mechanical properties of materials.