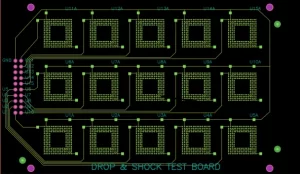

PCB Layout and Fabrication

In response to board level reliability testing, Cheetah Inspection Inc. offers assistance to clients in designing test boards according to the specifications of the test standards.

To monitor for any abnormalities in components during the testing process, a Daisy chain design is incorporated between the components and the circuit board. This design, upon assembly, forms a continuous circuit. The integrity of the circuit is then assessed by measuring its resistance, which helps determine if any failures have occurred.

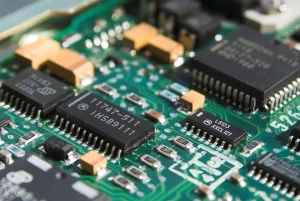

SMT Reflow and PTH Wave Soldering

We offer a one-stop assembly service, encompassing everything from part placement, solder paste SPI (Solder Paste Inspection) to reflow soldering processes, culminating in the complete fabrication of PCBA.

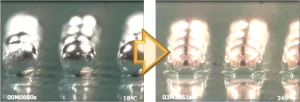

SMT Scope

The object to be observed is heated following a pre-set heating curve. Observation of the object during the soldering process is conducted through cameras positioned at the side and above the equipment, allowing for the monitoring of phenomena that occur due to heating.

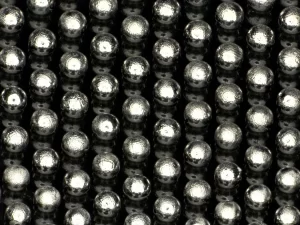

BGA Ball Mount and Reball

Cheetah Inspection Inc. assists clients in removing BGA from PCBs, then clearing any residual solder. Subsequently, solder balls of the corresponding size are reflow soldered onto the BGA to form solder joints. After soldering, the BGA can be cleaned as per the client’s requirements.

Component Solderability Test

Solderability of components can be assessed either by the wetting balance method using a solderability tester or through the SMT simulation method according to J-STD-002.